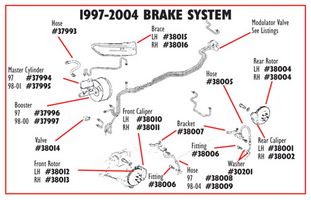

Corvette Brakes

The typical brake system consists of disk brakes in front and either disk or drum brakes in the rear connected by a system of tubes and hoses that link the brake at each wheel to the master cylinder. Other systems that are connected with the brake system include the parking brakes, power brake booster and the anti-lock system.

Brake Hydraulics:

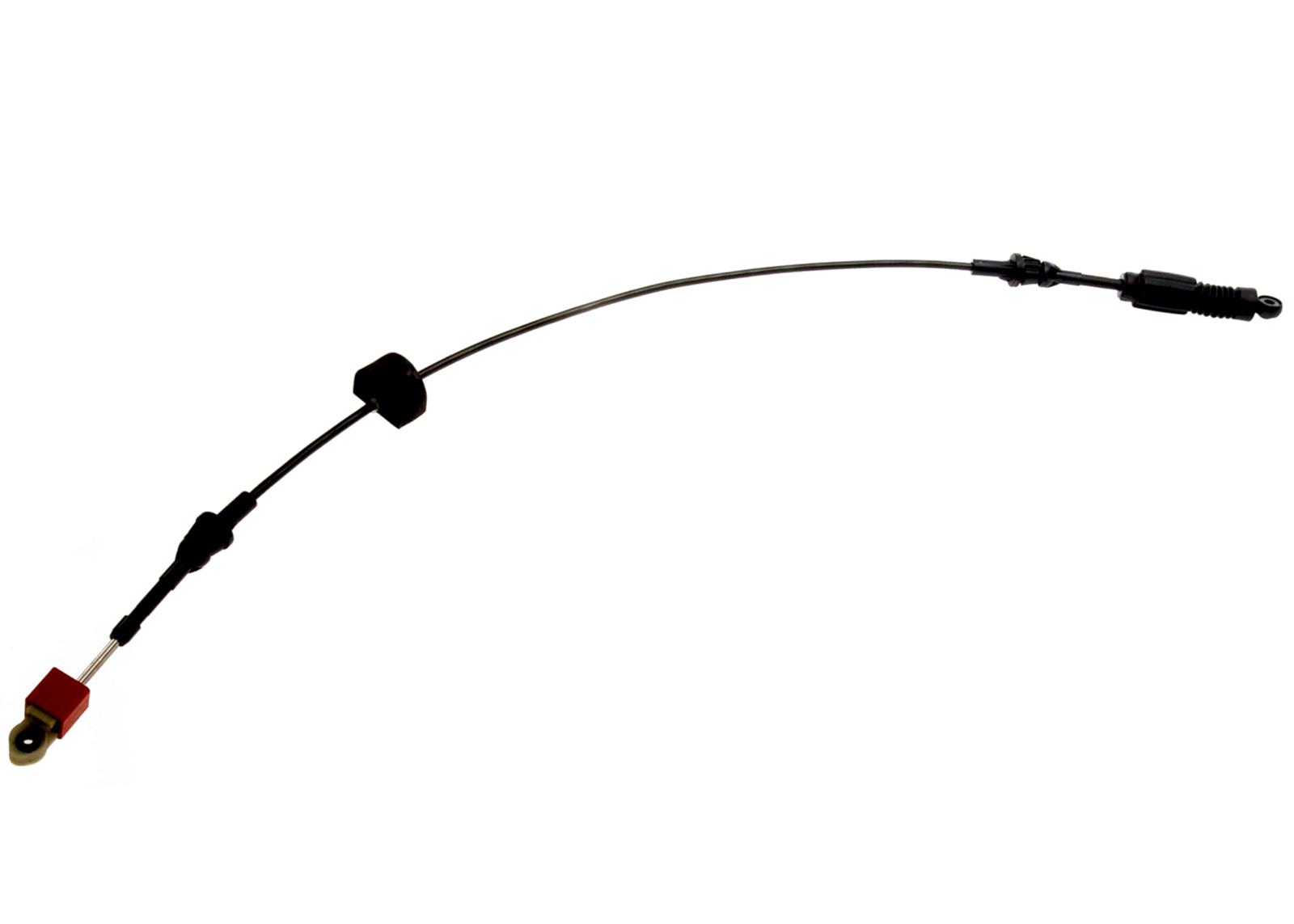

When you step on the brake pedal, you are actually pushing

against a plunger in the master cylinder, which forces hydraulic oil (brake

fluid) through a series of tubes and hoses to the braking unit at each wheel.

Since hydraulic fluid (or any fluid for that matter) cannot be compressed,

pushing fluid through a pipe is just like pushing a steel bar through a

pipe. Unlike a steel bar, however, fluid can be directed through many

twists and turns on its way to its destination, arriving with the exact same

motion and pressure that it started with. It is very important that the

fluid is pure liquid and that there are no air bubbles in it. Air can

compress, which causes a sponginess to the pedal and severely reduced braking

efficiency. If air is suspected, then the system must be bled to remove

the air. There are "bleeder screws" at each wheel cylinder and caliper for this

purpose.

Disk Brake Assembly: On a disk brake, the

fluid from the master cylinder is forced into a caliper where it presses against

a piston. The piston, in-turn, squeezes two brake pads against the disk (rotor),

which is attached to the wheel, forcing it to slow down or stop.

This process is similar to a bicycle brake

where two rubber pads rub against the wheel rim creating friction.

Brake Pads

There

are two brake pads on each caliper. They are constructed of a metal "shoe" with

the lining riveted or bonded to it. The pads are mounted in the

caliper, one on each side of the rotor. Brake linings used to be made

primarily of asbestos because of its heat absorbing properties and quiet

operation; however, due to health risks, asbestos has been outlawed, so new

materials are now being used. Brake pads wear out with use and must be

replaced periodically. There are many types and qualities of pads available. The

differences have to do with brake life (how long the new pads will last) and

noise (how quiet they are when you step on the brake). Harder linings tend to

last longer and stop better under heavy use but they may produce an irritating

squeal when they are applied. Technicians that work on brakes usually have a

favorite pad that gives a good compromise that their customers can live

with.

Brake pads should be checked for wear

periodically. If the lining wears down to the metal brake shoe, then you will

have a "Metal-to-Metal" condition where the shoe rubs directly against the rotor

causing severe damage and loss of braking efficiency. Some brake pads come with

a "brake warning sensor" that will emit a squealing noise when the pads are worn

to a point where they should be changed. This noise will usually be heard

when your foot is off the brake and disappear when you step on the brake.

If you hear this noise, have your brakes checked as soon as possible.

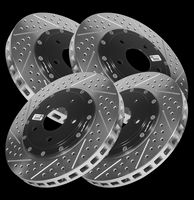

Rotor

The disk

rotor is made of iron with highly machined surfaces where the brake pads contact

it. Just as the brake pads wear out over time, the rotor also undergoes

some wear, usually in the form of ridges and groves where the brake pad rubs

against it. This wear pattern exactly matches the wear pattern of the pads

as they seat themselves to the rotor. When the pads are replaced, the

rotor must be machined smooth to allow the new pads to have an even contact

surface to work with. Only a small amount of material can be machined off

of a rotor before it becomes unusable and must be replaced. A minimum

thickness measurement is stamped on every rotor and the technician doing the

brake job will measure the rotor before and after machining it to make sure it

doesn't go below the legal minimum. If a rotor is cut below the minimum,

it will not be able to handle the high heat that brakes normally

generate. This will cause the brakes to "fade," greatly reducing their

effectiveness to a point where you may not be able to stop!

Caliper & Support

There are two main types of calipers: Floating

calipers and fixed calipers. There are other configurations but these are the

most popular. Calipers must be rebuilt or replaced if they show signs of

leaking brake fluid.

Corvette Brakes, brembo, ssi nserts, pads, rotors, calipers, brake fluid, caliper paint, stainless steel brake lines, hawk, gm performance, porterfield

New Products For October

|

- Shopping Cart 0 items

Corvette Attack Blue Dry Nano High Flow Filter, C8 Stingray, Z51 LT2

C6 "CORVETTE" Mirror Finish Rear Stainless Steel Letter Inserts, Fits all Model C6 Corvette